You Are Here:Home > Information dynamic

> Industry Trends

News Navigation

What is the stability of formaldehyde free ENF grade environmentally friendly particleboard

source:www.gq31.cn Time:2025-01-20

Formaldehyde free ENF grade environmentally friendly particleboard performs well in terms of stability, thanks to various factors such as raw materials, adhesives, and production processes, as follows:

1. Characteristics of raw materials

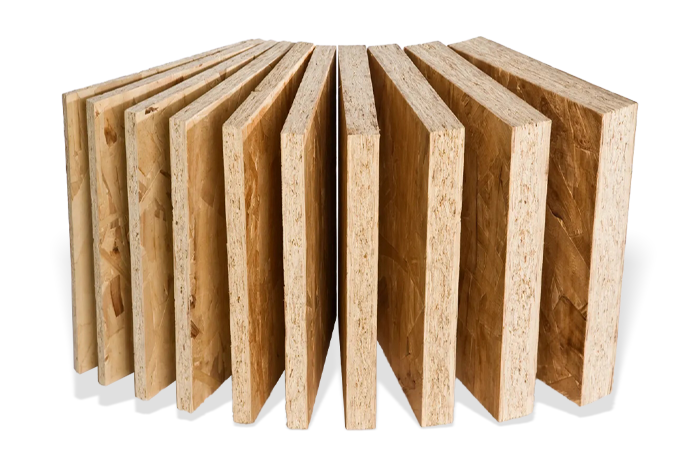

Wood particle uniformity: Formaldehyde free ENF grade environmentally friendly particleboard is usually made of high-quality wood and processed by specialized equipment into particles of relatively uniform size and shape. These uniform particles can be arranged more tightly and orderly during the paving and forming process, making the board structure stable. For example, in production, wood particles are screened and graded to ensure that the particle specifications of the same batch of boards are consistent, avoiding uneven density of boards due to large differences in particles and enhancing stability.

Wood fiber properties: The fiber structure of wood itself endows particleboard with a certain degree of cohesion. Excellent wood fibers are long and have good toughness, interweaving with each other to form a network structure, enhancing the internal bonding strength of the board. If wood with good fiber properties such as pine is used, its long fibers will fully bond with the adhesive during the hot pressing process, so that the board can effectively disperse stress when subjected to external forces, and is not easily deformed or cracked.

2. Performance of formaldehyde free adhesive

Chemical stability: This type of particle board uses formaldehyde free adhesives, such as MDI (isocyanate) adhesives. MDI has stable chemical properties, and the chemical bonds formed after reacting with wood particles can remain stable for a long time and are not easily affected by environmental factors to break. Compared to traditional aldehyde adhesives, MDI can maintain good bonding performance under different temperature and humidity conditions, ensuring the stability of the board structure.

Moisture resistance: MDI adhesive has good waterproof properties and can effectively prevent moisture from entering the interior of the board. In humid environments, the board will not expand or deform due to water absorption. For example, formaldehyde free ENF grade environmentally friendly particleboard produced with MDI adhesive usually has a much lower water absorption thickness expansion rate than normal standards, and can maintain good dimensional stability even when used in areas with high relative humidity such as bathrooms and kitchens.

3. Good production process

Proper control of hot pressing process: During the production process, the hot pressing process is crucial for the stability of the sheet metal. By correctly controlling the hot pressing temperature, pressure, and time, the wood particles can fully fuse with the adhesive to form a stable structure. Appropriate hot pressing temperature can fully react MDI adhesive, pressure ensures tight bonding of particles, and time ensures sufficient reaction. For example, good hot pressing equipment can control the temperature within ± 2 ℃, minimize pressure fluctuations, and produce boards with uniform density and good stability.

Post processing technology: After hot pressing, formaldehyde free ENF grade environmentally friendly particleboard will undergo a series of post processing, such as health preservation treatment. The board is placed in a specific temperature and humidity environment for a period of time to release internal stress and further stabilize the board structure. The possibility of deformation caused by incomplete release of internal stress during subsequent use of the board after health treatment is greatly reduced.

1. Characteristics of raw materials

Wood particle uniformity: Formaldehyde free ENF grade environmentally friendly particleboard is usually made of high-quality wood and processed by specialized equipment into particles of relatively uniform size and shape. These uniform particles can be arranged more tightly and orderly during the paving and forming process, making the board structure stable. For example, in production, wood particles are screened and graded to ensure that the particle specifications of the same batch of boards are consistent, avoiding uneven density of boards due to large differences in particles and enhancing stability.

Wood fiber properties: The fiber structure of wood itself endows particleboard with a certain degree of cohesion. Excellent wood fibers are long and have good toughness, interweaving with each other to form a network structure, enhancing the internal bonding strength of the board. If wood with good fiber properties such as pine is used, its long fibers will fully bond with the adhesive during the hot pressing process, so that the board can effectively disperse stress when subjected to external forces, and is not easily deformed or cracked.

2. Performance of formaldehyde free adhesive

Chemical stability: This type of particle board uses formaldehyde free adhesives, such as MDI (isocyanate) adhesives. MDI has stable chemical properties, and the chemical bonds formed after reacting with wood particles can remain stable for a long time and are not easily affected by environmental factors to break. Compared to traditional aldehyde adhesives, MDI can maintain good bonding performance under different temperature and humidity conditions, ensuring the stability of the board structure.

Moisture resistance: MDI adhesive has good waterproof properties and can effectively prevent moisture from entering the interior of the board. In humid environments, the board will not expand or deform due to water absorption. For example, formaldehyde free ENF grade environmentally friendly particleboard produced with MDI adhesive usually has a much lower water absorption thickness expansion rate than normal standards, and can maintain good dimensional stability even when used in areas with high relative humidity such as bathrooms and kitchens.

3. Good production process

Proper control of hot pressing process: During the production process, the hot pressing process is crucial for the stability of the sheet metal. By correctly controlling the hot pressing temperature, pressure, and time, the wood particles can fully fuse with the adhesive to form a stable structure. Appropriate hot pressing temperature can fully react MDI adhesive, pressure ensures tight bonding of particles, and time ensures sufficient reaction. For example, good hot pressing equipment can control the temperature within ± 2 ℃, minimize pressure fluctuations, and produce boards with uniform density and good stability.

Post processing technology: After hot pressing, formaldehyde free ENF grade environmentally friendly particleboard will undergo a series of post processing, such as health preservation treatment. The board is placed in a specific temperature and humidity environment for a period of time to release internal stress and further stabilize the board structure. The possibility of deformation caused by incomplete release of internal stress during subsequent use of the board after health treatment is greatly reduced.

Previous:

Application of odorless E0 grade environmentally …

Next:

What are the applications of odorless E0 environm…

Related products

+

wechat number:底部微信

Home

Home

Wechat

Wechat

Tell

Tell