You Are Here:Home > Information dynamic

> Industry Trends

News Navigation

What are the characteristics of moisture proof green environmental friendly particleboard

source:www.gq31.cn Time:2024-11-12

Moisture resistant green and environmentally friendly particleboard has the following characteristics:

1. Good moisture resistance:

Low water absorption and expansion rate: In humid environments, compared with ordinary particleboard, moisture-proof green and environmentally friendly particleboard greatly reduces the degree of water expansion. It undergoes special moisture-proof treatment or adds moisture-proof agents during the production process, so that even if the board comes into contact with a certain amount of moisture, it can maintain good dimensional stability and is not prone to deformation, warping and other problems, extending the service life of the board. It is particularly suitable for places with high humidity such as kitchens and bathrooms.

Good waterproof performance: The surface of the board usually has a certain degree of waterproofness, which can effectively block the penetration of moisture and prevent moisture from entering the interior of the board, thereby reducing the decline in board performance caused by moisture erosion. For example, the board can still maintain good strength and stability even after prolonged exposure to water or in humid environments.

2. Green environmental friendliness:

Environmental protection of raw materials: Its raw materials mainly come from wood processing residues, such as sawdust, wood chips, tree branches, etc., which realizes the recycling and utilization of resources, reduces the logging of natural wood, and is conducive to the protection of forest resources. At the same time, these raw materials are screened and processed to ensure that they do not contain harmful substances or impurities, ensuring the environmental friendliness of the board from the source.

Adhesive environmental protection: The adhesive used is usually in compliance with environmental standards, such as low formaldehyde or formaldehyde free adhesives. This results in a lower release of harmful substances such as formaldehyde during the production and use of the board, reducing indoor air pollution and ensuring people's health.

Recyclability: After the end of its service life, the board can be recycled and reused, reducing the generation of waste and meeting the requirements of sustainable development.

3. Stable physical performance:

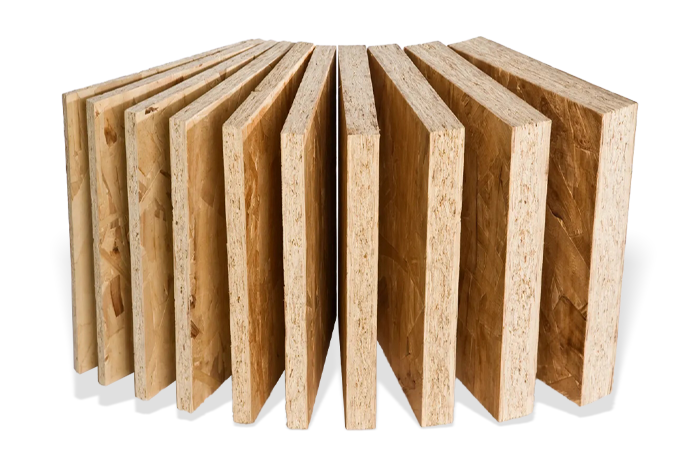

Uniform structure: The interior of particleboard is made up of granular particle materials bonded by adhesive, with a relatively uniform structure and good isotropy. Therefore, when subjected to external forces, it can evenly distribute stress and is less prone to damage caused by local uneven stress.

High strength: After undergoing high-temperature and high-pressure processing, the board has high strength and can withstand certain weight and pressure, making it suitable for making products such as furniture, cabinets, flooring, etc. that require a certain load-bearing capacity.

Not easy to deform and crack: Good structure and strength make the board less prone to deformation and cracking under different environmental conditions, such as temperature and humidity changes, ensuring the quality and stability of the product.

4. Good processing performance:

Easy to cut: The texture of the board is relatively soft, and it can be easily cut using ordinary cutting tools such as saws, cutting machines, etc., which can meet the processing needs of various shapes and sizes, and facilitate the production of different styles of furniture and decoration components.

Easy edge banding: Edge banding is a very important step in the furniture production process. The edges of moisture-proof green and environmentally friendly particleboard are relatively flat, easy to perform edge sealing treatment, and the effect after edge sealing is good, which can effectively prevent the release of harmful substances such as moisture and formaldehyde.

Surface decoration can be carried out: The surface of the board is flat and smooth, and various surface decoration treatments can be carried out, such as veneering, painting, printing, etc., which can meet the needs of different consumers for product appearance and achieve diversified design effects.

5. Economical: Due to its wide range of raw material sources, relatively simple production processes, and high production efficiency, compared with some natural wood panels or other high-end artificial panels, moisture-proof green and environmentally friendly particleboard has a relatively low price and high cost-effectiveness, which can meet the needs of mass consumers.

1. Good moisture resistance:

Low water absorption and expansion rate: In humid environments, compared with ordinary particleboard, moisture-proof green and environmentally friendly particleboard greatly reduces the degree of water expansion. It undergoes special moisture-proof treatment or adds moisture-proof agents during the production process, so that even if the board comes into contact with a certain amount of moisture, it can maintain good dimensional stability and is not prone to deformation, warping and other problems, extending the service life of the board. It is particularly suitable for places with high humidity such as kitchens and bathrooms.

Good waterproof performance: The surface of the board usually has a certain degree of waterproofness, which can effectively block the penetration of moisture and prevent moisture from entering the interior of the board, thereby reducing the decline in board performance caused by moisture erosion. For example, the board can still maintain good strength and stability even after prolonged exposure to water or in humid environments.

2. Green environmental friendliness:

Environmental protection of raw materials: Its raw materials mainly come from wood processing residues, such as sawdust, wood chips, tree branches, etc., which realizes the recycling and utilization of resources, reduces the logging of natural wood, and is conducive to the protection of forest resources. At the same time, these raw materials are screened and processed to ensure that they do not contain harmful substances or impurities, ensuring the environmental friendliness of the board from the source.

Adhesive environmental protection: The adhesive used is usually in compliance with environmental standards, such as low formaldehyde or formaldehyde free adhesives. This results in a lower release of harmful substances such as formaldehyde during the production and use of the board, reducing indoor air pollution and ensuring people's health.

Recyclability: After the end of its service life, the board can be recycled and reused, reducing the generation of waste and meeting the requirements of sustainable development.

3. Stable physical performance:

Uniform structure: The interior of particleboard is made up of granular particle materials bonded by adhesive, with a relatively uniform structure and good isotropy. Therefore, when subjected to external forces, it can evenly distribute stress and is less prone to damage caused by local uneven stress.

High strength: After undergoing high-temperature and high-pressure processing, the board has high strength and can withstand certain weight and pressure, making it suitable for making products such as furniture, cabinets, flooring, etc. that require a certain load-bearing capacity.

Not easy to deform and crack: Good structure and strength make the board less prone to deformation and cracking under different environmental conditions, such as temperature and humidity changes, ensuring the quality and stability of the product.

4. Good processing performance:

Easy to cut: The texture of the board is relatively soft, and it can be easily cut using ordinary cutting tools such as saws, cutting machines, etc., which can meet the processing needs of various shapes and sizes, and facilitate the production of different styles of furniture and decoration components.

Easy edge banding: Edge banding is a very important step in the furniture production process. The edges of moisture-proof green and environmentally friendly particleboard are relatively flat, easy to perform edge sealing treatment, and the effect after edge sealing is good, which can effectively prevent the release of harmful substances such as moisture and formaldehyde.

Surface decoration can be carried out: The surface of the board is flat and smooth, and various surface decoration treatments can be carried out, such as veneering, painting, printing, etc., which can meet the needs of different consumers for product appearance and achieve diversified design effects.

5. Economical: Due to its wide range of raw material sources, relatively simple production processes, and high production efficiency, compared with some natural wood panels or other high-end artificial panels, moisture-proof green and environmentally friendly particleboard has a relatively low price and high cost-effectiveness, which can meet the needs of mass consumers.

Previous:

Application of ENF board is used in the construct…

Next:

What are the applications of ENF board is used in…

Related products

+

wechat number:底部微信

Home

Home

Wechat

Wechat

Tell

Tell